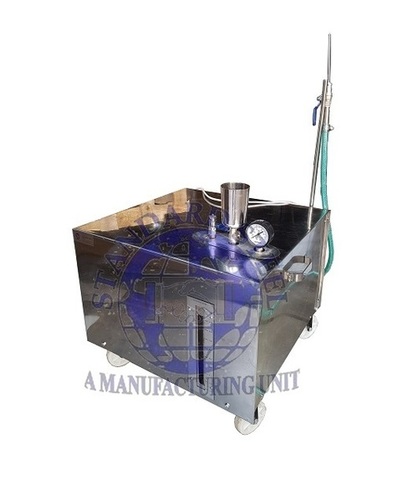

Embalming Machine

Embalming Machine Specification

- Accuracy

- 1% (Pressure Gauge)

- Product Type

- Embalming Machine

- Height

- 38 cm

- Power

- 1/8 HP Motor

- Properties

- Corrosion Resistant, Leak Proof Vessel, Movable with Wheels, Easy Handling

- Suitable For

- Human and Animal Cadavers

- Temperature Range

- Ambient

- Dimension (L*W*H)

- Approx. 50 x 30 x 38 cm

- Treatment Type

- Embalming Fluid Administration

- Application

- For Embalming, Disinfecting & Preserving Dead Bodies

- Weight

- Approx. 18-22 kg

- Material

- Stainless Steel

- Color Code

- Silver

- Display Type

- Dial

- Shape

- Rectangular

- Use

- Medical, Hospital Mortuary, Pathological use

- Frequency

- 50 Hz

- Storage Capacity

- 8-12 Litres (Fluid Tank)

- Phase

- Single Phase

- Function

- Fluid Injection under Pressure

- Automation Grade

- Semi-Automatic

- Power Source

- Electric

- Voltage

- 220-240 V

- Motor Type

- Heavy Duty Sealed Motor

- Pipe Material

- Medical Grade PVC

- Safety Features

- Overload Thermal Protection

- Mobility

- Fitted with Castor Wheels for Easy Movement

- Finish Type

- Polished

- Flow Control

- Adjustable Pressure Regulator

- Cleaning

- Easy to Dismantle and Clean

- Tank Material

- Rustproof Stainless Steel

- Noise Level

- Low Noise Operation

- Included Accessories

- Injector Pipe, Pressure Gauge, Power Cord

Embalming Machine Trade Information

- Minimum Order Quantity

- 01 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 10 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Export Packing

- Main Domestic Market

- All India

- Certifications

- ISO CE

About Embalming Machine

Embalming Machine

- The body of the Embalming Machine(Cadaverous Injector) machine is made of Stainless Steel/ Mild Steel (As required).

- For injecting formaldehyde solution in cadaverous at much higher speed than normal gravity process.

- Unit is fully covered & mounted on a portable trolley having four castor wheels for easy movement.

- Unit consists of one air compressor which is connected with a stainless steel tank of 10 liters capacity meant for storing and injecting the solution.

- Incorporated with latest Reciprocatory pressuring unit for efficient performance.

- The machine is Completely Noiseless and Vibration free which justifies the Superiority of our machine from the other brands available.

- Tank is fitted with a safety valve, pressure gauge and rubber tubing having provision for injection.

- Supplied complete with electric cord, plug and suitable to work on 220 volts, 1ph 50 hz.

Highly Durable Construction

Built using rustproof stainless steel and medical-grade PVC, this embalming machine is engineered for long-term reliability and resistance to corrosion. The leak-proof design, robust structure, and easy-to-clean surfaces make it exceptionally suitable for intensive use in hospitals and mortuaries.

Precision and Safety Features

Equipped with an adjustable pressure regulator, heavy-duty sealed motor, and accurate dial-type pressure gauge (1%), this machine ensures safe and controlled fluid injection. Overload thermal protection enhances operational safety, safeguarding both users and the equipment.

Ease of Movement and Maintenance

With fitted castor wheels, the machine is easily movable within working spaces. Its modular structure allows for convenient dismantling and cleaning, minimizing downtime and facilitating routine hygiene protocols for mortuary and hospital environments.

FAQs of Embalming Machine:

Q: How is the embalming fluid injected using this machine?

A: The embalming fluid is administered under controlled pressure through a medical-grade PVC injector pipe, managed by an adjustable pressure regulator and accurate pressure gauge. This ensures precise and safe delivery during the embalming process.Q: What are the main benefits of the polished stainless steel construction?

A: The polished stainless steel body offers corrosion resistance, easy cleaning, and a hygienic surface, ensuring durability and compliance with medical sanitation standards required in mortuary and hospital use.Q: When should routine cleaning and maintenance be performed?

A: Cleaning should be performed after each use or daily in high-volume environments. The machines easy-to-dismantle design allows for thorough cleaning and maintenance to ensure optimal hygiene and reliable function.Q: Where can this embalming machine typically be used?

A: This embalming machine is suitable for use in hospitals, mortuaries, pathology labs, and veterinary facilities, serving both human and animal cadaver preparations.Q: What process is followed for setting up the machine for use?

A: To set up, position the machine using the castor wheels, ensure it is on a level surface, connect to electric power (220-240 V, 50 Hz), attach the injector pipe, fill the stainless steel tank with embalming fluid, and adjust the pressure gauge before commencing fluid injection.Q: What are the features that make this machine safe to operate?

A: Key safety features include overload thermal protection, a leak-proof vessel, single-phase operation, and low-noise performance. The sealed motor and firm castor brakes further enhance user and operational safety.Q: How does the adjustable pressure regulator aid the embalming process?

A: The adjustable pressure regulator enables the operator to control the force and rate at which embalming fluid is delivered, allowing for precise treatment tailored to varying requirements, ensuring efficient preservation and disinfection.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Anatomy Equipment Category

Anatomy Cadaver storage Tank

Price 52000.0 INR

Minimum Order Quantity : 1 Pieces

Material : stainless steel

Product Type : Anatomy cadaver storage tank

Suitable For : Medical Colleges, Research Labs, Hospitals

Use : Dead Body Storage Tank

Dead Body Concealment Trolley for Cadaver Transportation

Price 36500.0 INR

Minimum Order Quantity : 1 Pieces

Material : stainless steel

Product Type : Dead Body Concealment Trolley for Cadaver Transportation

Suitable For : Dead Body Concealment Trolley for Cadaver Transportation

Use : Dead Body Concealment Trolley for Cadaver Transportation

Electro Hydraulic Autopsy Postmortem Table

Price 115000.0 INR

Minimum Order Quantity : 1 Pieces

Material : Stainless Steel

Product Type : Mortuary Room Autopsy Table

Suitable For : Postmortem Table

Use : Electro Hydraulic Autopsy Table

Cadaver Tank

Price 78000.0 INR / Piece

Minimum Order Quantity : 1

Material : Stainless Steel

Product Type : Dead Body Storage Tank Cadaver Tank

Suitable For : Dead Body Storage Tank Cadaver Tank

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese